Decorative Coatings metal finishing

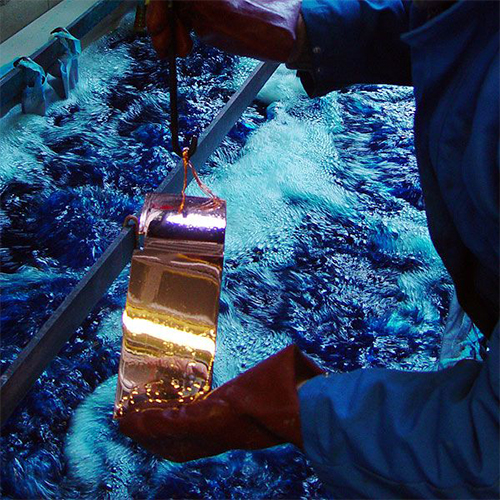

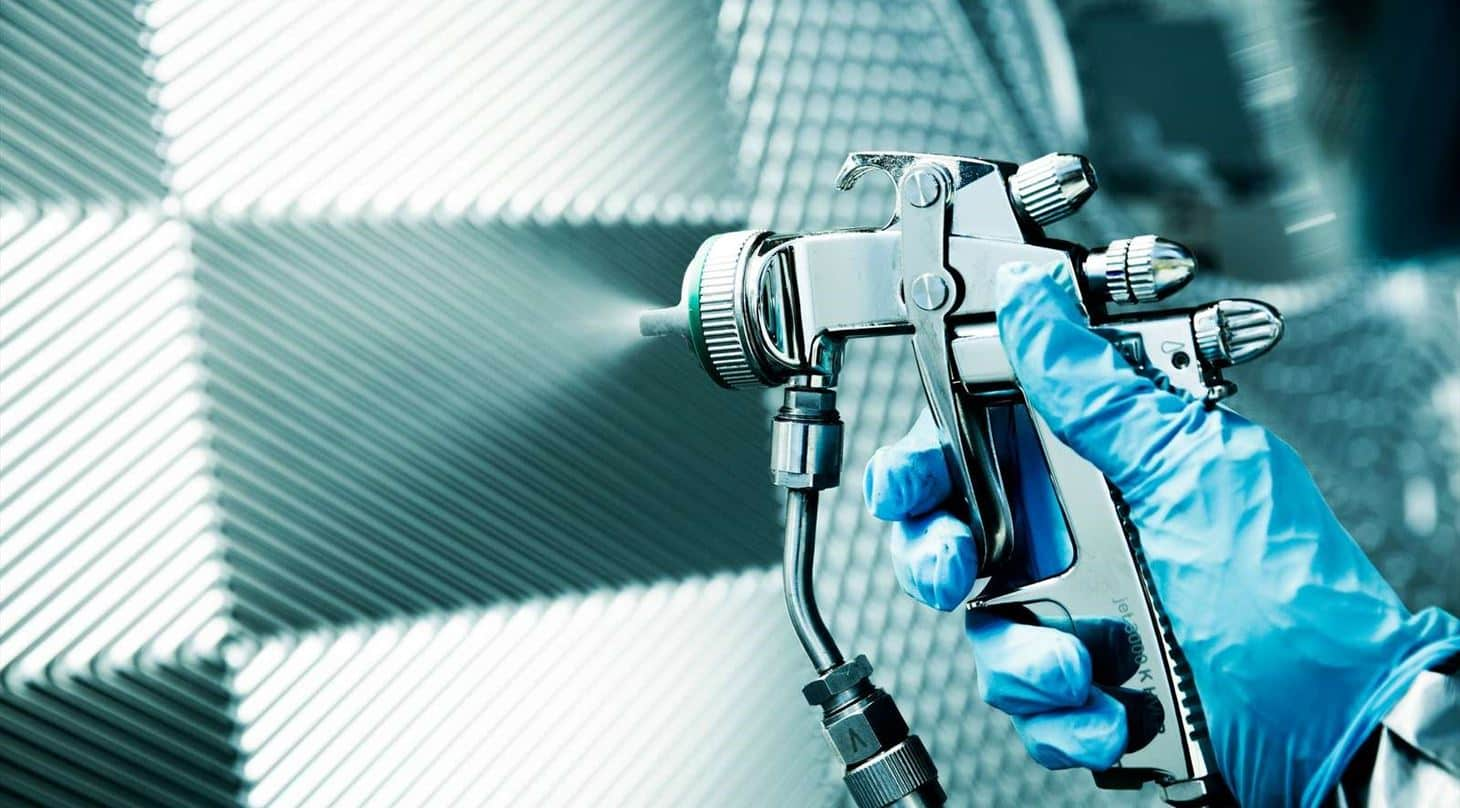

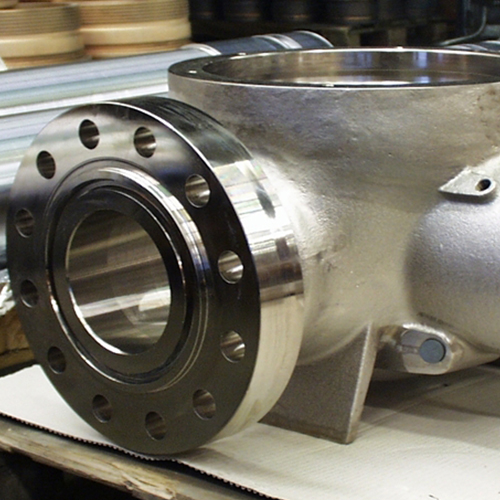

Metal finishing practice in decorative electroplating is work directed towards attaining better durability of decoratively plated articles. Decorative electroplating is the process used to add a new metal finish on top of metal and plastic parts.

Primary reasons of decorative plating are to enhance the quality of the parts used internally or externally. A key benefit of electroplating process is that it offers increased lifespan and enhance the functionality of the product, while also meeting end-user’s aesthetic requirements.